Maximize Stability And Performance: A Comprehensive Guide To Rubber Mounts

Rubber mounts are essential for maximizing stability and performance across various applications, such as automotive vehicles, HVAC systems, industrial machinery and electronic appliances. Properly selecting and utilizing this machinery part can significantly enhance the functionality and efficiency of any equipment. This guide will delve into the world of rubber mounts, their types, properties and benefits. Moreover, we will also explore various applications and provide insights into the importance of proper installation and maintenance practices. After reading this guide, you will be able to understand how rubber mounts contribute to stability and performance optimization in diverse settings.

The pursuit of seamless operations, enhanced safety, and improved user experiences lie in stability and performance in various applications. By incorporating rubber mounts, it is possible to mitigate the adverse effects of vibrations, movements, and shocks, leading to increased lifespan and operational efficiency of the equipment.

As we go deeper into this article, you will discover rubber mounts' crucial roles in achieving optimal stability and performance. If you are a machinery operator, automotive enthusiast, an HVAC technician or simply interested in understanding the working process of systems, this guide will equip you with valuable knowledge. Let's embark on this informative journey and explore how rubber mounts can revolutionize stability and performance in many applications.

Understanding rubber mounts

Rubber mounts are specifically designed to provide stability and performance in various applications. To appreciate the importance of this equipment, it is essential to learn about their types, properties and the factors that influence their selections.

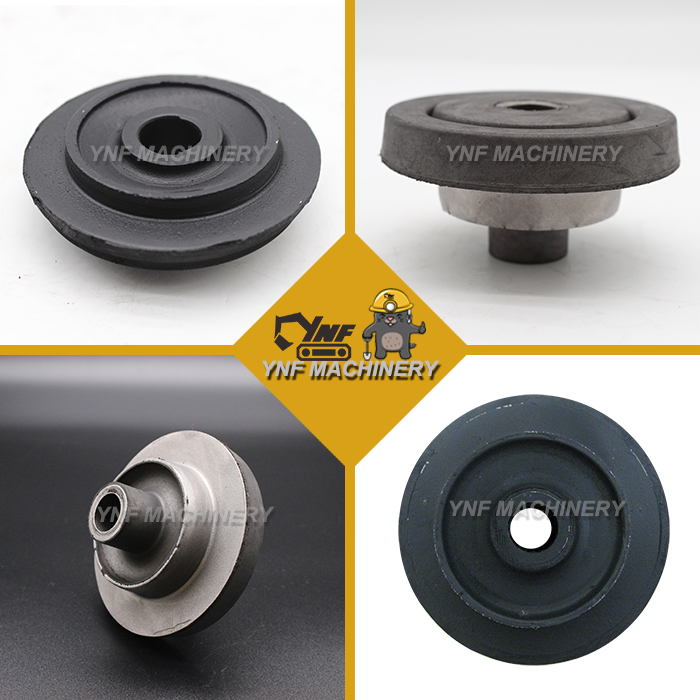

Definition And Composition Of Rubber Mounts

Rubber mounts are engineered devices made from rubber elements and other supporting components. Those rubber elements are typically made of synthetic elastomers that are the primary medium for absorbing shocks, vibration and other dynamic forces. Its unique properties enable it to dampen vibration while giving a certain degree of resilience.

The supporting components of rubber mounts include studs, metal plates and mounting hardware. These elements are integrated to ensure the proper installation and secure attachment to the structure or equipment.

Types Of Rubber Mounts

Rubber mounts are available in different types; each is designed to meet the specific application requirement. Following are the three most common types of rubber mounts.

1.Compression Mounts

Compression mounts are used to support heavy loads and absorb vertical vibrations. They are made from cylindrical rubber elements encased within metal plates. The rubber compression during the installation process provides the necessary capacity, which is load bearing.

2.Shear Mounts

Shear mounts excel at isolating horizontal shocks and vibrations. They feature a rubber element with metal plats attached to each side. This rubber element deflects in shear, effectively absorbing force exerted in different directions.

3.Stud Mounts

Stud or sandwich mounts are designed to assist in stability and vibration isolation in vertical and horizontal directions. They consist of a central metal stud sandwiched between two rubber elements. The stud enables easy installation and secure attachment to the structure.

Properties Of Rubber Mounts

The rubber mount properties contribute to an ideal performance and effectiveness in vibration isolation and stability enhancement. The following are some fundamental properties to consider:

●Damping Characteristics

Rubber mounts exhibit inherent damping properties that disperse and absorb vibration, minimizing the energy transmission to the surrounding structures or equipment.

●Resilience

The resilience of rubber mounts directs to their ability to return to their original shape after undergoing deformation. This property is essential in sustaining effectiveness and performance in the long run.

●Load Capacity

Rubber mounts are engineered to withstand specific load capacities. It is crucial to select mounts that can support the anticipated loads to ensure optimum performance and prevent premature failure.

●Vibration Isolation

Rubber mounts excel in isolating vibrations and preventing their propagation to surrounding components. They absorb and dissipate vibrations, minimizing the impact on performance and improving the stability of the equipment.

Factors Influencing the Selection of Rubber Mounts

When selecting rubber mounts for a particular application, it is crucial to consider several factors:

●Environmental Conditions

Environmental factors such as exposure to chemicals, temperature variations, UV radiation or moisture can affect the longevity and performance of rubber mounts. Therefore, selecting mounts with proper material properties and resistance to specific environmental conditions is crucial.

●Load Requirement

The anticipated load, including static and dynamic forces, must be assessed accurately to determine the proper load capacity of the rubber mounts.

●Application Specifics

Understanding the requirement of the application, such as space constraints, mounting options and alignment considerations, is vital in making the right choice of rubber mounts.

●Vibration and Shock Levels

The frequency and magnitude of socks and vibrations expected in the application should be analyzed to choose rubber mounts with suitable damping characteristics and isolation capabilities.

While purchasing, by considering the above factors and understanding the properties and types of rubber mounts, you can make informed decisions regarding maintaining stability and performance in your application.

The following section will explore the benefits rubber mounts offer across various systems and industries.

Benefits Of Rubber Mounts

Rubber mounts provide numerous benefits regarding maximizing stability and performance in different kinds of applications. Let's explore some critical advantages of them:

●Minimizing Vibrations

Rubber mounts dampen vibrations generated by engines, machinery or equipment. By dissipating and absorbing the vibration, the rubber mounts prevent them from propagating to surrounding equipment, reducing the risk of damage and ensuring smoother operations.

●Preventing Machinery Movement

Rubber mounts act as a focal point securing equipment and preventing unwanted movement. They maintain the proper alignment and position of machinery, enhancing stability and reducing the risk of malfunction and accidents.

●Reducing Noise Levels

Vibrations often lead to noise levels which can harm the entire performance and user experience. Rubber mounts isolate vibration, thus decreasing noise transmission and creating a quieter working environment.

●Extending Equipment Lifespan

Excessive vibrations and shocks can accelerate wear and tear on equipment components. By effectively absorbing and minimizing these dynamic forces, rubber mounts help extend the lifespan of machinery, reducing maintenance costs and downtime.

●Protecting Components and Structures:

Vibrations and shocks can cause damage to sensitive components or structures. Rubber mounts provide a cushioning effect, absorbing these forces and protecting equipment from excessive stress, ensuring longevity.

●Ensuring Operator Comfort

In applications where operators work close to vibrating machinery, rubber mounts provide a more comfortable and ergonomic working environment. By reducing vibrations, they help minimize operator fatigue and enhance overall safety.

The benefits of rubber mounts are not limited to specific industries or applications. They have a wide range of uses and offer advantages across various sectors:

●Automotive Industry

Rubber mounts are extensively employed in engine mounts to isolate engine vibrations and reduce noise transmission. They are also used in suspension systems to improve ride comfort and stability.

●Industrial Machinery

Heavy equipment mounts utilize rubber mounts to isolate vibrations from machinery such as compressors, generators, and pumps. This ensures smoother operations, reduces equipment damage, and enhances overall productivity.

●HVAC Systems

Rubber mounts play a vital role in HVAC systems, isolating vibrations in air handling, chillers, and condensing units. This minimizes noise and vibration transmission, ensuring efficient and quiet operation.

●Electronics and Appliances

In consumer electronics and appliances, rubber mounts are employed in audio equipment to reduce vibrations and provide clear sound output. They are also used in washing machines to minimize vibrations and prevent excessive movement during spin cycles.

Industries and applications can achieve optimal stability, performance, and safety by harnessing the benefits of rubber mounts. It is important to select the appropriate rubber mounts based on the specific requirements of each application to ensure maximum effectiveness. In the next section, we will explore the diverse applications of rubber mounts across different industries.

Applications of Rubber Mounts

Rubber mounts find extensive applications in various industries and systems where stability, vibration isolation, and performance optimization are crucial. Let's explore some typical applications of rubber mounts across different sectors:

Automotive Industry

●Engine Mounts

Rubber mounts are used in engine mounts to isolate engine vibrations and reduce the transmission of vibrations to the vehicle's chassis. This enhances the overall driving experience, reduces noise, and prevents excessive wear on engine components.

●Suspension System

Rubber mounts play a vital role in the suspension system of vehicles. They help absorb shocks and vibrations, providing a smoother ride, improved handling, and better vehicle stability.

Industrial Machinery

●Heavy Equipment Mounts

Rubber mounts are employed in heavy machinery, such as construction equipment, industrial pumps, and large-scale generators. They isolate vibrations and shocks, reducing equipment wear, enhancing stability, and improving the overall efficiency of operations.

●Generators and Compressors

Rubber mounts are utilized in generators and compressors to isolate vibrations and prevent their transmission to the surrounding structures. This minimizes noise, enhances equipment performance, and reduces maintenance requirements.

HVAC Systems

●Air Handling Units

Rubber mounts are commonly used in air handling units to isolate vibrations caused by fans, blowers, and motors. This prevents the propagation of vibrations to the building structure and ensures quiet operation.

●Chillers and Condensing Units

Rubber mounts are critical in isolating vibrations in chillers and condensing units. By minimizing vibrations, they improve the efficiency and performance of these systems while reducing noise levels.

Electronics and Appliances

●Audio Equipment

Rubber mounts are employed in audio equipment, such as speakers and subwoofers, to isolate vibrations and prevent their transmission to the surrounding surfaces. This enhances sound quality and reduces unwanted resonances.

●Washing Machines

Rubber mounts are utilized in washing machines to minimize vibrations and prevent excessive movement during the spin cycle. This enhances stability, reduces noise, and prevents damage to the machine and surrounding structures.

These are just a few examples of the broad range of applications where rubber mounts play a vital role in achieving stability and performance optimization. From automotive vehicles to industrial machinery, HVAC systems, and consumer appliances, rubber mounts are essential components that ensure smooth operations, reduce vibrations and enhance overall functionality.

Conclusion

Rubber mounts are indispensable components in many applications, maximizing stability and performance. Rubber mounts play a pivotal role in enhancing the functionality and efficiency of various systems by effectively absorbing vibrations, isolating shocks, and providing stability.

Throughout this comprehensive guide, we have explored rubber mounts' definitions, types, properties, and benefits. We have seen how they contribute to minimizing vibrations, reducing noise levels, extending equipment lifespan, and ensuring operator comfort. From automotive engines and suspension systems to industrial machinery, HVAC systems, and consumer electronics, rubber mounts find applications in diverse industries, improving overall performance and safety.

Proper installation and maintenance practices are crucial to harnessing rubber mounts’ advantages. Careful consideration of load requirements, environmental conditions, and application specifics ensures the selection of the most suitable rubber mounts. Additionally, adhering to recommended installation procedures, torque specifications, and routine maintenance, such as inspection, cleaning, and lubrication, will help maximize the longevity and effectiveness of rubber mounts.

By adequately incorporating rubber mounts and maintaining them properly, industries can achieve optimal stability, minimize equipment wear, reduce noise, and enhance overall performance. Whether it's reducing vibrations in a vehicle's engine, isolating shocks in heavy machinery, or improving the efficiency of HVAC systems, rubber mounts offer a reliable solution for stability and performance optimization.

In conclusion, rubber mounts are essential for maximizing stability and performance in their respective applications. By understanding the types, properties, and benefits of rubber mounts and their diverse applications, industries and individuals can make informed decisions and leverage the advantages they offer. Through careful selection, proper installation, and regular maintenance, rubber mounts can contribute significantly to achieving seamless operations, extended equipment lifespan, and improved user experiences.